Shape transformation is ubiquitous in our daily lives, occurring in a multitude of forms, ranging from instantaneous change to gradual evolution. Now, researchers at Zhejiang University have pioneered an innovative way of altering shapes. Once triggered, the shape Transformer enters a dormant state for a period of time before starting its transformation. The duration of the dormant period can be manually controlled, much like adjusting a timer. In reality, the entire Transformer is merely a homogenous hydrogel, akin to the familiar substances we consume, such as jellies and tofu.

How can such a simple material achieve a precisely timed response? In an article titled Shape memory polymer with programmable recovery onset published in the journal Nature on September 13th, the research team led by Prof. XIE Tao and Prof. ZHAO Qian from the College of Chemical and Biological Engineering at Zhejiang University illuminated the intricacies of the shape-shifting mechanism. This innovative approach to programmable shape transformation holds immense promise in fields such as deep-space/deep-sea exploration and biotechnology, as in many real-world scenarios, a timed response is a better solution than an immediate response.

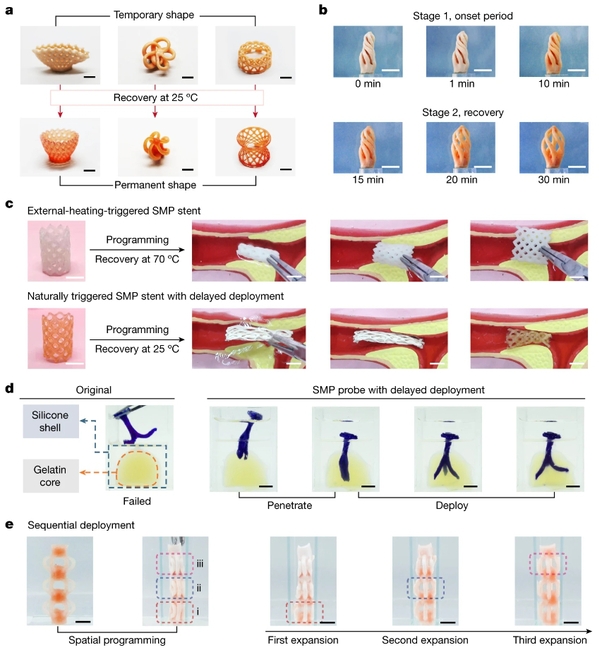

Device demonstrations of the 4D printable shape memory hydrogel.

In 2020, Prof. GONG Jianping from Hokkaido University in Japan reported a new type of hydrogel that exhibits thermally activated rigidity change. Based on his understanding of shape memory polymers, Prof. XIE Tao speculated that this hydrogel could be used as a potential shape memory material.

After a series of experiments, the research team found that this hydrogel is characterized by its distinctive delayed transformation properties. Not only does it possess remarkable shape memory, but it also ‘knows’ when to recover its memory. Its rebound is not merely delayed; it follows a precise schedule.

Why does it exhibit an exceptionally long reflex arc? The answer to this enigma lies in a unique shape-shifting mechanism.

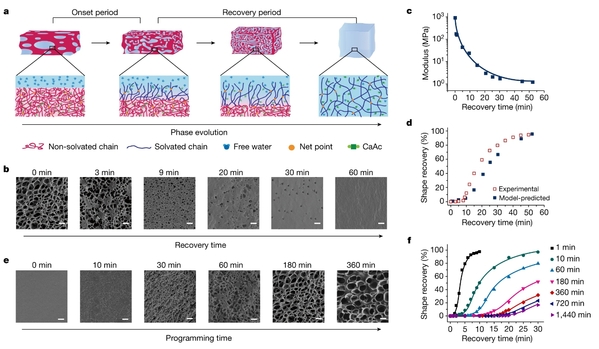

When a material undergoes a shift from hot to cold, it experiences a delicate interplay between two competing forces: one trying to maintain its temporary shape and the other working to restore its original shape. In the very beginning, the force responsible for maintaining the temporary shape gains a decisive edge, with the difference between the two forces exceeding three orders of magnitude. “This dynamic can be likened to a little rabbit attempting to pull out a carrot. At the beginning, the carrot is buried deep, and the soil is hard, so it can’t be pulled out,” ZHAO Qian explained. For a long time, the material remains locked in its temporary shape, seemingly unchanged to naked eyes. As time elapses, the ‘soil’ becomes loose, meaning the force maintaining the temporary shape continues to wane. When the disparity between the two forces diminishes to a point where it is no longer significant, the material undergoes a visible transformation. Research shows that when the difference in force drops to 20 times, the material will undergo a 5% transformation.

The team, in collaboration with Prof. KONG Xueqian at Shanghai Jiao Tong University, identified more underlying reasons employing ultra-high-field nuclear magnetic resonance imaging. “This material possesses two types of water: one involves bound water inside the polymer phase, while the other is free water between polymer phases. When the material is subjected to heating and ‘implanted’ with a temporary shape, a significant phase separation will occur, resulting in a low structural water content and heightened material hardness. Cooling down involves a process of phase fusion during which the bound water content gradually increases and the material becomes softer,” said Prof. ZHAO Qian. When the material’s bound water content reaches 70%, visible shape-shifting behavior will occur.

Mechanism of the naturally triggered shape memory with delayed recovery onset.

“Unlike ordinary shape memory dominated by thermal conduction, timed shape-shifting behavior is driven by the diffusion of water molecules,” said ZHAO Qian. It is for this very reason that the length of the ‘reflex arc’ hinges on the specific time at which the material is programmed to maintain its temporary shape at high temperatures, a parameter commonly referred to as the thermal programming time. The longer the thermal programming time, the longer the time for free water to diffuse within the material, and the greater the degree of phase separation.

With the insightful understanding of this mechanism, scientists harnessed the power of delay to craft timing. The operation is straightforward, involving precise control over the thermal programming time. Currently, the longest dormant period achievable is 46 minutes. With this control method, the research team managed to orchestrate an astonishing gymnastics performance by the Transformer: the body, the left hand, and the right hand underwent stretches and movements successively and smoothly. This feat was accomplished by pre-setting different thermal programming times for different positions of the material, resulting in varying dormant periods and a carefully choreographed order of transformation.

“Trigger-response” represents a fundamental interaction between the natural world and society. “We need materials to respond as required when exposed to stimuli, but we also hope they can undergo ‘spontaneous transformation’ without any external stimulus. This is a paradox, but it’s also a demand,” said Prof. XIE Tao. “This demand is particularly prominent in the realm of biomedical devices. For example, some devices should be capable of responding to light or heat triggers, but the triggering signal often cannot penetrate deep into the human body, hindering the occurrence of the desired response. Another challenge arises when spontaneous transformation happens too quickly. The device transformation starts before it is reaches its target location. This stands as a bottleneck for many implantable biomedical devices.”

4D-printed timed transformation vascular stent.

The research team posited that devices exhibiting timed transformation hold significant promise in the fields of biomedical engineering and deep-space/deep-sea exploration. In their research paper, they conceptually demonstrated a 4D printed vascular stent capable of timed transformation. This stent is designed to undergo a specific temporal sequence from the moment it enters the body until it reaches its intended site. Notably in such a scenario, a traditional shape memory stent material would deploy prematurely due to triggering by body temperature. The devices with timed transformation, with their inherent ‘dormant period’, have the advantage of initiating the transformation process only after arriving at the precise target location.