March 9, 2021

New Research Developments in Synthetic Biology

Recently, the research group of Associate Prof. Li dan Ye & Prof. Hongwei Yu from the College of Chemical and Biological Engineering at Zhejiang University(ZJU CBE), makes a progress in Vitamin E heterologous biosynthesis.

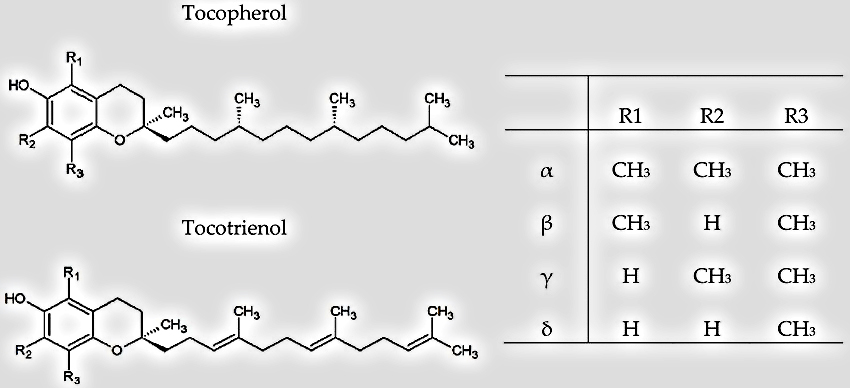

Vitamin E is an essential vitamin to maintain the normal metabolism and function of the body. It contains eight compounds, including α,β,γ, δ-tocopherol and α,β,γ,δ-tocotrienol (Fig. 1). The main vitamin E products on the market are chemical synthesis of racemic DL-α-tocopherol and a small amount of natural α-tocopherol extracted from plants. The former is mainly used for animal nutrition, and the latter is used for dietary supplements.

Fig.1 The chemical structure formula of vitamin E

Compared with tocopherol, tocotrienol has stronger antioxidant properties and unique physiological functions such as cholesterol lowering, neuroprotection and cancer-combating properties, which has a broader application prospect. At present, there are corresponding dietary supplements on the market abroad (Fig. 2), consisted of four kinds of natural tocotrienols extracted from plants. Although the chemical synthesis of DL - α - tocopherol is very mature and low-cost, tocotrienol hasn’t been commercialized and is relatively rare in plant distribution, which limits its further development and application.

Fig.2 Natural tocotrienol dietary supplements abroad

On October 14, the research group of Ye Lidan / Yu Hongwei of Zhejiang University published a paper entitled "Ferrous production of vitamin E tocotrienols in Saccharomyces cerevisiae under cold shot triggered temperature" on Nature Communications(DOI:10.1038/s41467-020-18958-9). The total biosynthesis of α - tocotrienol was realized in Saccharomyces cerevisiae engineering strains, which laid an important foundation for the production of this series of products by fermentation. The first author of this paper is Shen bin, a graduate student of the research group.

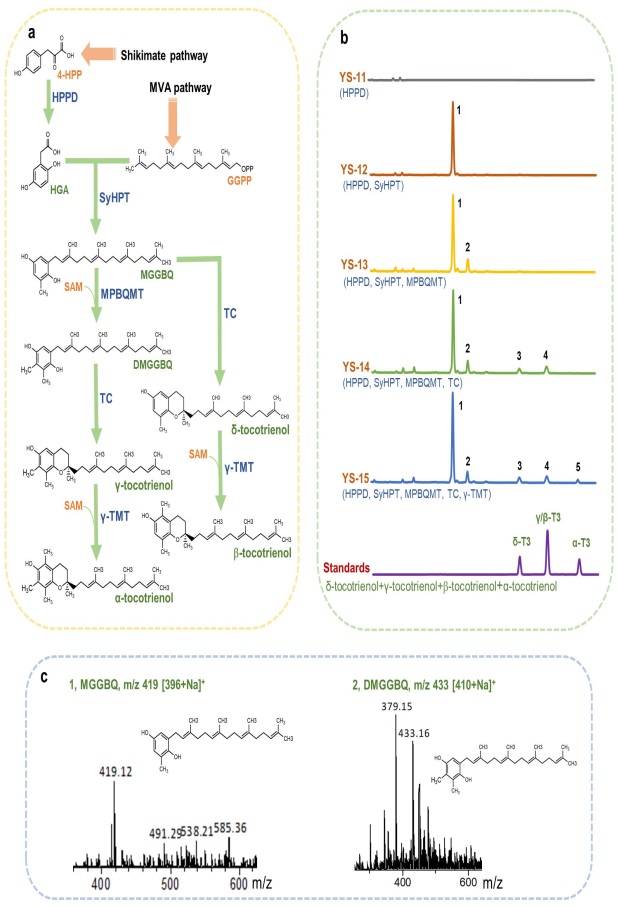

Fig.3 Tocotrienol synthesis pathway and five key genes used in this study

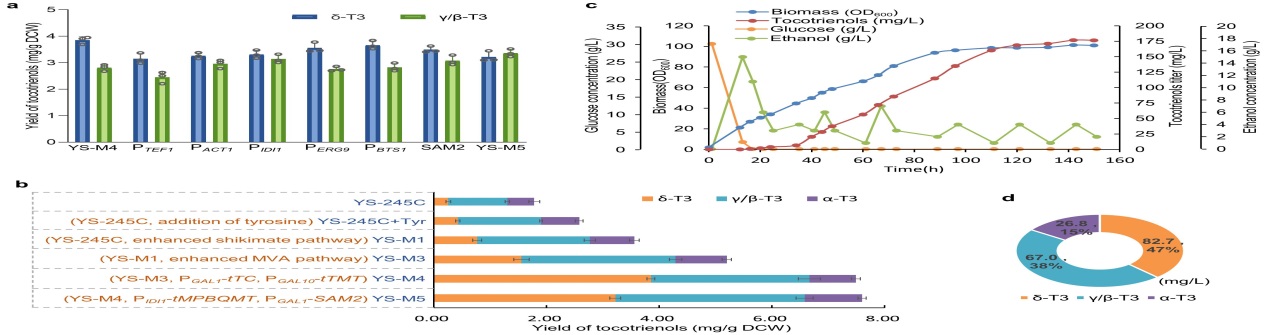

In this study, five key gene elements for the synthesis of tocotrienol were found and screened in 14 photosynthetic organisms (Fig. 3). Combined with codon optimization and precise excision of protein precursor chain, and combined with shikimic acid pathway and MVA pathway of Saccharomyces cerevisiae, heterologous synthesis of the final product α - tocotrienol was successfully realized in non photosynthetic organisms. Further, through a series of system transformation of engineering strains, such as determining and removing the key speed limiting steps of synthetic pathway, comprehensive optimization of upstream pathway, release of feedback inhibition, and reconstruction of metabolic balance, the total tocotrienol yield of 7.6 mg/G cell dry weight was achieved in shake flask culture, which was 23.3% higher than that of the primary strain.(Fig.4)

Fig.4 Improvement of tocotrienol biosynthesis by Saccharomyces cerevisiae through multi strategy systematic transformation

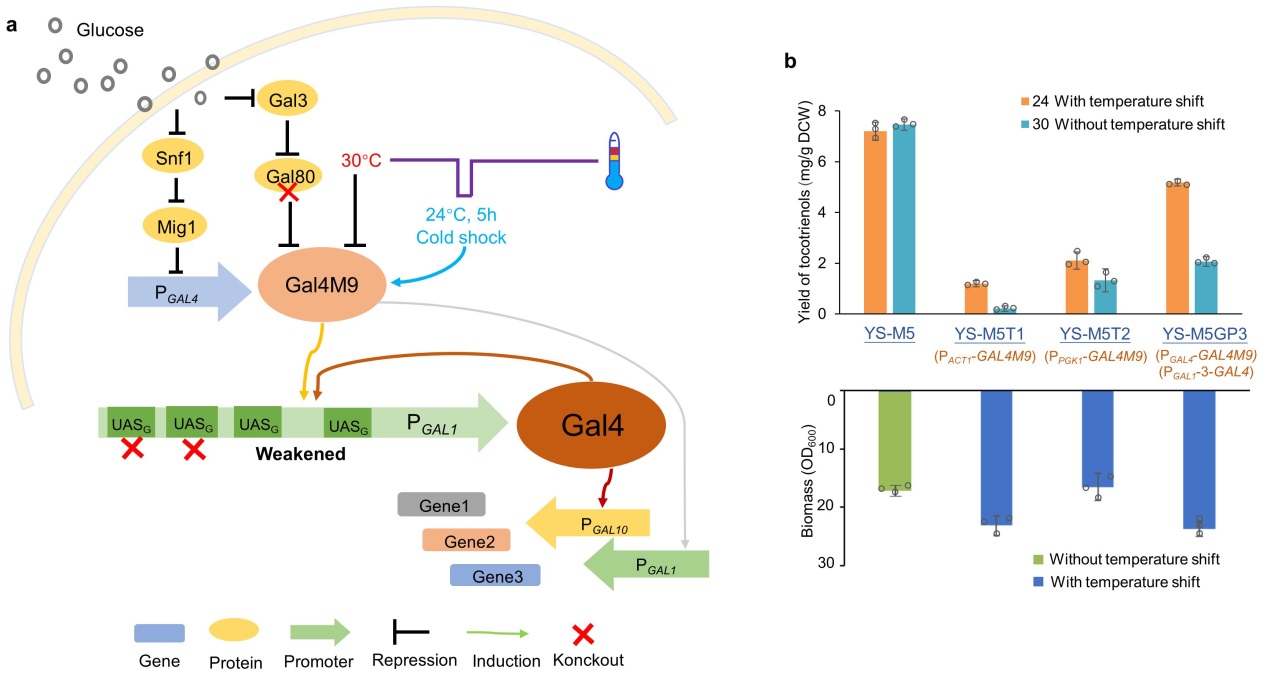

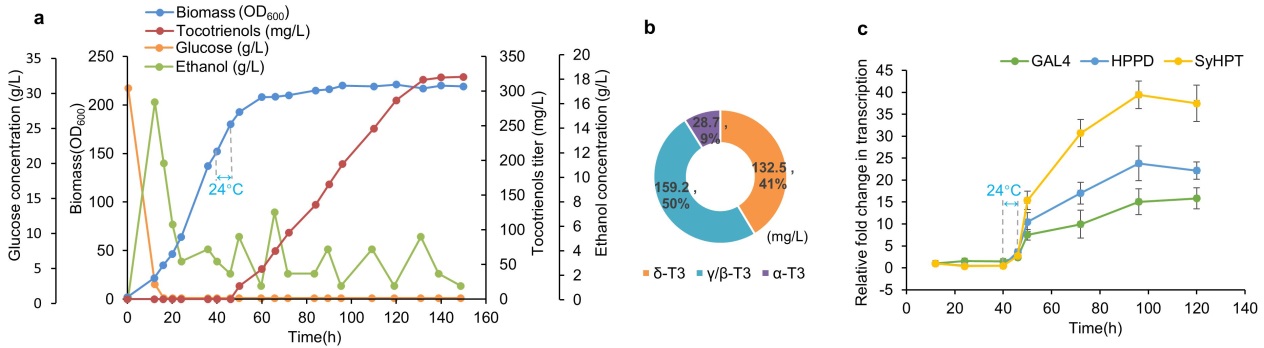

In order to balance cell growth and product synthesis, the author further introduced hierarchical regulation based on the Gal4 thermosensitive protein Gal4M9 developed in the early stage of the research group, and drove the expression of wild type Gal4 by the thermosensitive protein Gal4M9 (Fig. 5).

Fig.5

Cold shock control strategy to achieve phased accumulation of biomass and target products

By adopting a new temperature control strategy, it only takes several hours of cold shock to trigger the switch of product synthesis. Compared with the temperature control induction system that needs to maintain product synthesis at low temperature, the upgraded system has the following advantages:

1) it makes up for the loss of Gal4M9 activity, and customizes the expression intensity of transcription activating protein Gal4 according to the needs of the pathway.

2) it greatly reduces the production cost The cost of energy consumption in the process of industrial fermentation was reduced.

3) the side effect of long-term low temperature on physiological metabolism of the strain was avoided. Combined with the newly designed cold shock temperature control system, the phased control of cell biomass accumulation and target product accumulation of the engineering strain producing tocotrienol was successfully realized. Finally, the total tocotrienol production reached 320 mg/L in 5L fermentor, which laid the foundation for the realization of full fermentation production of natural Vitamin E.

Fig. 6 Cold shock control strategy to control gene expression and synthesize natural tocotrienols

In general, this research integrated the multi gene biosynthetic pathway assembly, new gene mining, protein engineering, gene expression control and other means, and finally realized the synthesis of natural tocotrienols using eukaryotic chassis, which is an important step forward in the production of high value-added plant natural products using synthetic biology.

In the past decade or so, ye Lidan / Yu Hongwei's research group has adopted Saccharomyces cerevisiae as the chassis organism, and successively applied in the following aspect:the biosynthetic pathway of the assembly mode, (Decentralized Assembly, Biotechnology and Bioengineering 2014), strategy of gene expression sequence regulation (Sequential Control, Metabolic Engineering, 2015), the development of pathway assembly tools (pMRI, pUMRI series carrier tools), the combination of enzyme engineering and metabolic engineering (Metabolic Engineering, 2015; 2017), the compartmentalization of biosynthetic pathway (Nature Communications, 2016), the transformation of gal regulatory system, and the creation of temperature sensitive Gal4 (low temperature active Gal4M9, Biotechnology and Bioengineering, In this study, we continue to upgrade the level of Gal4 regulation (low temperature triggered regulation). At the same time, in the development of bulk chemicals (isoprene), pigment series (Lycopene, beta Carotene, Cantharidin, Astaxanthin, Lutein), vitamin series (Vitamin A, Vitamin D, Vitamin E), flavors and fragrances (such as Flavanone), and so on, they have made continuous progress and have good industrial application prospects.