In a groundbreaking development, two scientific research breakthroughs from Zhejiang University's College of Chemical and Biological Engineering have been simultaneously published in the prestigious international journal Science. On December 22nd, two teams, led by Professor Bai Hao and Professor Xiao Feng-shou, respectively, unveiled their remarkable findings.

Focusing on the first study, Professor Bai Hao and his team have successfully created a super-insulating artificial fiber through a fascinating process inspired by the fur of polar bears. Employing a core-shell structure, the fiber encapsulates aerogel, revolutionizing traditional thermal insulation materials. Moreover, it possesses the ability to block infrared radiation emitted by the human body. Notably, the fiber's mechanical properties, including its tensile strength, have been significantly improved. Importantly, this unique fiber can be directly woven, making it a practical innovation for wearable aerogel applications. The groundbreaking research paper, titled ''Biomimetic, knittable aerogel fiber for thermal insulation textile '', was published in Science on December 22nd.

The first study presents an artificial fiber that emulates the exceptional insulating properties found in polar bear fur. This fiber exhibits a distinctive "core-shell" structure, where a polymer aerogel core is surrounded by small, long pores measuring approximately 10-30 micrometers, arranged parallel to each other. These pores act as tiny air pockets, enhancing the fiber's insulation capacity. Additionally, the core is encased in a thermoplastic polyurethane (TPU) shell. This innovative fiber effectively inhibits heat radiation, heat convection, and heat conduction, greatly improving overall insulation performance. Unlike conventional insulating materials that rely on trapping air or vacuum, this fiber's orderly pore structure helps minimize heat radiation. The study also examines the fiber's stretch resistance, water washability, and dyeability.

New type of fiber, resistant to water washing, will not shrink after washing, and still maintains its warmth

Paper link:

https://www.science.org/doi/10.1126/science.adj8013

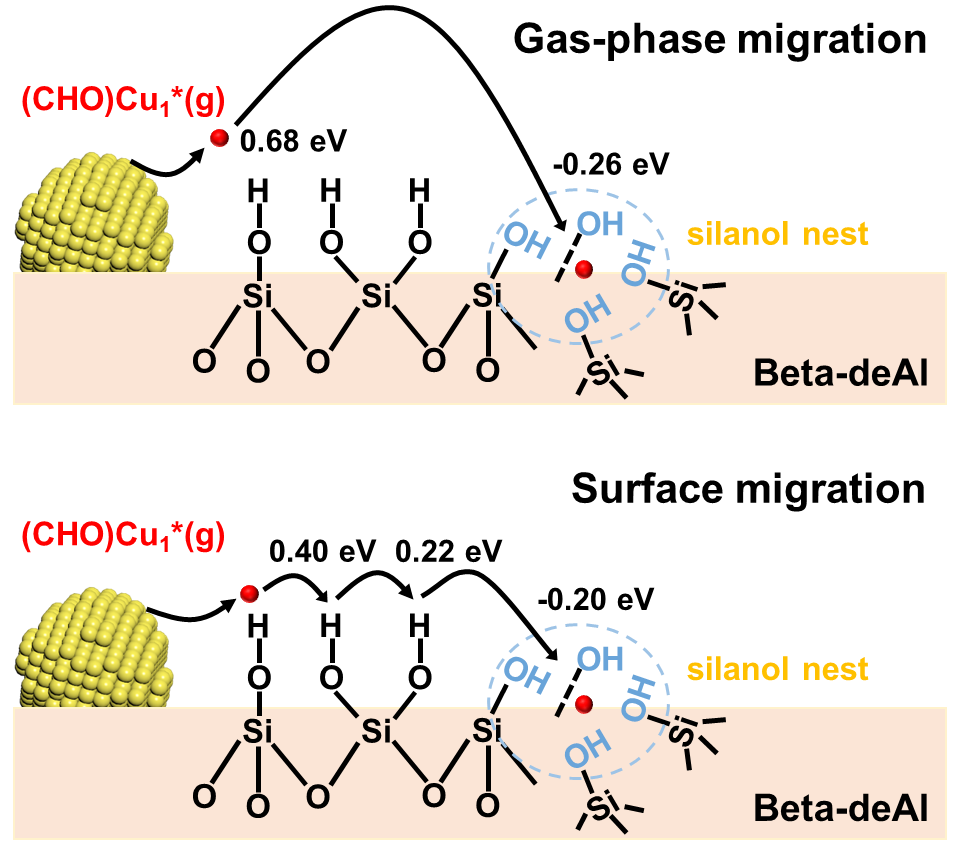

Moving on to the second study, Professor Xiao Feng-shou and Research Professor Wang Liang developed a novel strategy for durable catalyst design . By surface regulation of Beta zeolite, numbers of silanol nests are formed, and these sites serve as capturing the copper atom related intermediates during the Ostwald ripening process under reaction atmosphere. The anchored copper atom become new nucleation center to capture other active copper complex, leading to the formation of uniformly dispersed copper nanoparticles. This strategy reverses the conventional sintering process of supported copper-based catalysts. The remarkable research paper, titled "Dealuminated Beta zeolite reverses Ostwald ripening for durable copper nanoparticle catalysts," was published online in Science on December 22nd.

The second study provides a feasible avenue for the deactivation issues of copper catalysts in coal-to- ethylene glycol industry. Professor Xiao Feng-shou and Research Professor Wang Liang's group used dealuminated Beta zeolite as support to redisperse copper nanoparticles into smaller ones during dimethyl oxalate hydrogenation. The in situ formed copper nanoparticles demonstrated excellent catalytic performance and stability . This work offers experimental evidence in the chemical-triggering Ostwald ripening process for copper catalysts, and clarifies the mechanism for the redispersion process. The researchers emphasize that this dynamic regulation strategy is promising for the design and development of other durable supported metal catalysts.

Surface regulation of support to reverse Ostwald Ripening for the supported copper catalysts

Paper link:

https://www.science.org/doi/10.1126/science.adj1962