In terms of thermal insulation, polar bears serve as a walking ‘textbook.’ Enveloped in an ultra-insulating “sweater,” they can adapt to frigid temperatures as low as -40°C. Their fur, remarkable for its hollow structure, traps a significant volume of ‘still’ air, thereby reducing heat loss by inhibiting both heat conduction and convection. This principle has inspired the design of warm apparel, where textiles, such as wool and down feathers, excel in reducing heat transfer.

Fig. 1: A photo of polar bear fur under an optical microscope

In the quest for warm and lightweight materials, people tend to utilize fewer materials to encapsulate more air. Aerogels, known for their extraordinarily high porosity and a density smaller than that of air (over 90% of their total volume is air), is an ideal candidate for thermal insulation. Over the past few decades, endeavors have been made to ‘coat’ aerogels on the surface of fabrics or directly ‘spin’ fibers containing aerogels. However, these innovations face formidable challenges: aerogel coatings tend to peel off, the incorporation of aerogels into materials remains limited, and there are issues with wear resistance and stretchability. These hurdles continue to impede the advancement of next-generation thermal clothing.

Fig. 2: A polar bear fur coat made in 2018, woven with tweezers.

In 2018, a groundbreaking achievement was made in the lab at the Zhejiang University College of Chemical & Biological Engineering. Under the guidance of Prof. BAI Hao, a research team unveiled the first generation of ‘polar bear sweaters,’ capturing extensive attention in academic and industrial domains. These innovative garments, crafted from lightweight, porous fibers, showcased exceptional thermal insulation capabilities. However, their axial tensile strength left room for improvement. In an effort to encapsulate an experimental rabbit in this “polar bear sweater,” the team meticulously and painstakingly hand-knitted a blanket-like patch using tweezers.

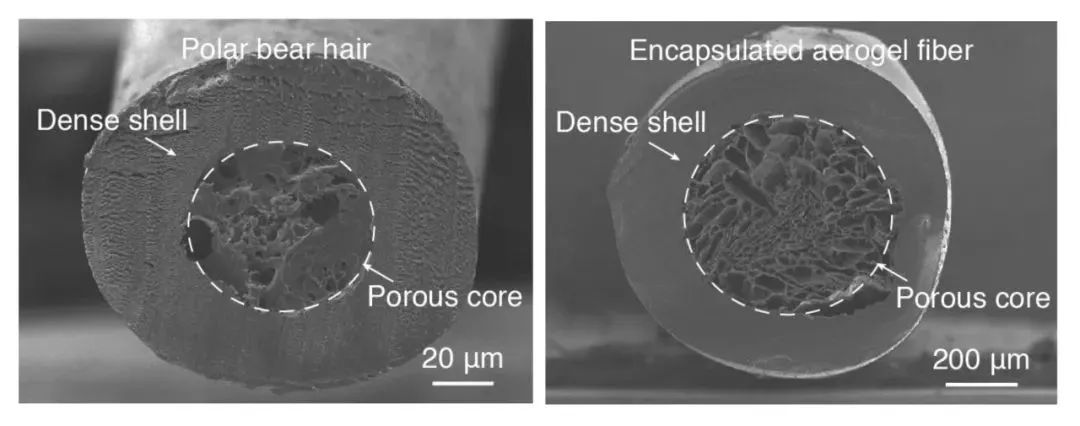

“The existing solutions fall short in simultaneously delivering warmth, lightness, and durability,” the team said, confronted with this multi-faceted challenge. In order to find a solution, they opened their unconventional “textbook” – polar bear fur. An overlooked detail from past observations became the cornerstone of their breakthrough: Not only is polar bear fur hollow, but it also has a shell! Under the electron microscope, this shell is about 20 microns thick, accounting for nearly a quarter of the hair’s diameter. It was this discovery that inspired the team to develop “Polar Bear Sweater 2.0.”

Fig. 3: SEM images of polar bear hair (left) and the encapsulated aerogel fiber (EAF) (right).

Drawing on the “core-shell” structure of polar bear fur, the team developed a new type of fiber after nearly 6 years of dedicated research. At its core lies a polymer aerogel, featuring elongated pores about 10-30 microns in diameter, all uniformly aligned in the same direction to ack like individual air storage "warehouses". Encasing this is a layer of TPU (thermoplastic polyurethane) shell, which envelops the internal aerogel. This innovative design allows each component--the core and the shell--to perform its distinct function.

Their findings were published in a research article titled “Biomimetic, knittable aerogel fiber for thermal insulation textile” in the journal Science on December 21.

Central to their discovery is the "core" mechanism that provides extraordinary insulation. “Warmth, to some extent, is about preventing the loss of heat,” explained WU Mingrui, the lead author of the article. Human heat loss primarily occurs through thermal radiation, convection, conduction, and sweat evaporation, among which thermal radiation has the most significant impact (accounting for 40-60%), with heat being lost in the form of infrared radiation. However, traditonal thermal clothing is often inadequate in mitigating this radiation. Some conventional materials, with disorderly nano-porous structures, are virtually “transparent” to infrared rays and thus unable to block infrared radiation. This inefficiency stems from their pore sizes being substantially smaller than the wavelength of infrared light.

By controlling the orientation and size of the pores within the fibers, it is possible to “trap” infrared radiation. “Infrared rays emanate from the surface of the skin. By orienting the pores perpendicular to the radiation and fine-tuning their size, we aim to match the wavelength of infrared rays, thereby successfully entrapping infrared radiation,” said WU Mingrui.

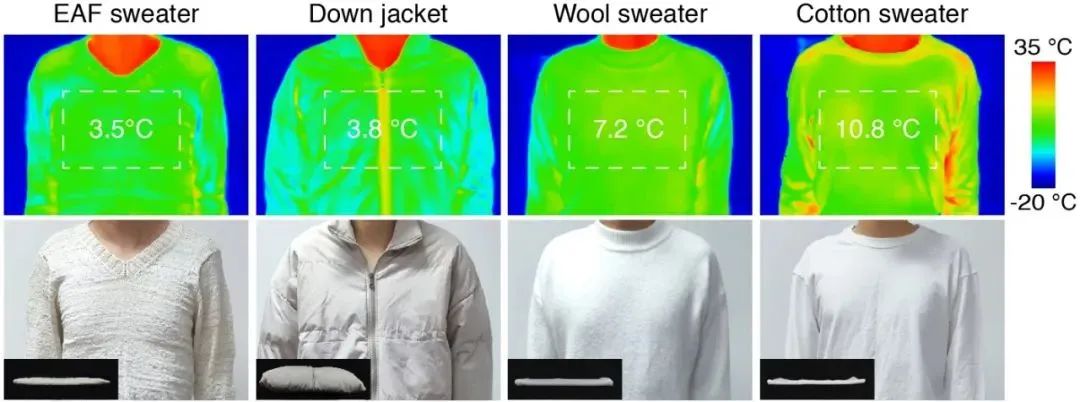

Fig. 4: A volunteer wearing our EAF textile, down jacket, and wool and cotton sweaters in a cold environment of –20°C.

To assess the thermal effectiveness of their innovation, the researchers converted a -20°C cold storage room in the canteen into an improvised “fitting room” for a “warmth-keeping challenge”. ZHANG Zibei, one of the co-authors, served as a model. He donned various garments, including a down jacket, a wool sweater, a cotton jersey, and a “polar bear sweater,” all pre-set to the same initial temperature. Measurements taken shortly after revealed that the surface temperature of the cotton jersey climbed to 10.8°C, while that of the down jacket increased to 3.8°C. Impressively, the “Polar Bear Sweater,” significantly thinner than the down jacket at approximately one-third to one-fifth its thickness, exhibited only a marginal temperature rise to 3.5°C. This lesser temperature increment indicates reduced heat loss from the body, marking the “Polar Bear Sweater 2.0” as a superior competitor in thermal insulation. “Owing to the lessened efficacy of down in blocking infrared rays, it requires substantially greater thickness to attain a comparable thermal effect,” said WU Mingrui.

“New aerogel fibers are revolutionizing thermal insulation thanks to their thermal radiation, convection, and conduction,” said Associate Professor GAO Weiwei, one of the lead researchers. “The key to inhibiting thermal conduction and convection lies in encapsulating as much air or vacuum as possible. Since our fibers have an orderly pore structure, they can inhibit thermal radiation simultaneously. This is how polar bear fur differs from ordinary hollow fibers.”

The “shell” plays a critical role in enhancing toughness and durability. “It acts like a skeleton, providing remarkable mechanical support for the fibers, making them wear-resistant, stretchable, and washable,” said Prof. BAI Hao. “For biomimetic fibers, overall performance is crucial, especially when compared to static insulators like crisper boxes. These fibers must withstand stretching, compression, washability, and resist thinning.”

Fig. 5: Tensile test of biomimetic polar bear hair fibers.

To this end, the team engineered a TPU shell for the fiber, a common elastic material. In rigorous tests, the new type of fiber could be stretched to twice its length without breaking, thus meeting the requirements for stretch resistance. These biomimetic fibers, prepared on a large scale in the lab, are compatible with commercial textile machinery, paving the way for direct weaving into fabrics.

“However, a stronger shell does not necessarily mean a better performance,” explained WU Mingrui. “An overly thick shell could compromise the insulation performance of the fiber. Therefore, we've optimized the shell to balance insulation and mechanical strength effectively.”

“Polar bear fur shows us how nature ingeniously solves problems through ‘decoupling’ design where the core and shell serve distinct yet complementary roles, jointly creating one of the most cold-resistant materials in the natural world. Our new aerogel fiber is inspired by this principle.” said Prof. BAI Hao.

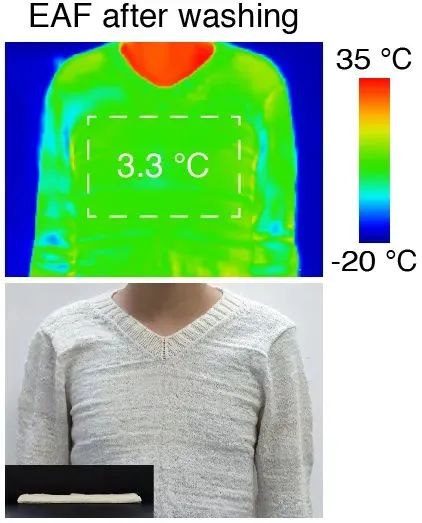

Fig. 6: IR image showing that the EAF sweater maintained its thermal insulation property at –20°C after washing, indicating its excellent washability.

In follow-up experiments, the team explored other features of biomimetic polar bear fur. Notably, the new fiber is not only wash-resistant, maintaining its size and thermal efficiency after washing, but it also readily accepts dyes, enhancing its practicality and aesthetic appeal.